Why Momentum BTB

- Identical single-lane printers are easily re-deployed to other lines when needed

- Maximum PCB size 609.6 mm x 508 mm (24” x 20”) [When running in dual lane configuration]

- Wet print accuracy of 20µm@6σ, Cpk ≥ 2, with 6σ Capability designed in and independently verified

- Smaller footprint - BTB 1.4 meter deep (55”)

- Overall length of 2.8m for the two machines

BENEFITS & FEATURES

Patented Single Camera Vision Alignment System

- MPM's Patented Look-Up/Look-Down technology ensure board-to-stencil alignment is accurate and repeatable

- No moving optical parts guarantee durability and reliability

- Flexibility to recognize unlimited number of fiducial image patterns through enhanced vision recognition strategies

Benchmark Software

- Window Operating System anchors Speedline's "Benchmark" software standard offering stability and ease of use

- Software developed, tested and released from Speedline Headquarters. No third party development ensuring software integrity

- Easy programming and on-board software wizards make programming and operation simple and efficient

- Touch screen friendly option available

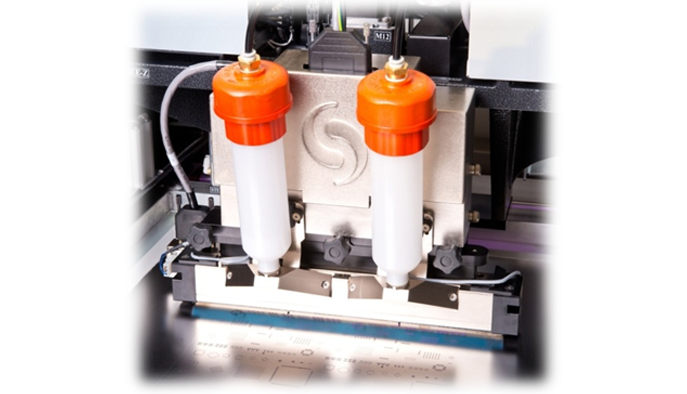

Patented Ultrawipe Stencil Cleaner

- Patented solvent bar delivers maximum control of solvent application increasing yields

- Paper over plenum design reduces maintenance by filtering particles through the paper

- Provides unassisted cleaning of the bottom of the stencil for maximum uptime and increased yields

- Improved paper routing for fast and easy change-over

- Low noise Vacuum pump housed within the printer frame

Closed-Loop Squeegee

- Motor Driven Squeegee System provides maximum force control

- Patent pending "calibration compliance routine" automatically compensates for varying blade length and stiffness to ensure consistent force

- Patent pending close loop squeegee option provides the highest level of accuracy and responsiveness

Post Print Inspection

- Contrast based 2D pad inspection, bridge detection and under stencil inspection to increase quality and yield

- Inspection results are quantified to the component pad level and on-board SPC makes analysis clear and precise

- Speedline's patented texture based inspection sees paste between pads and surrounding stencil apertures to prevent defects

EnclosedFlow Print Head

- Excellent print results for fine feature devices

- Tremendous savings on print media compared to squeegee blades

- Ability to address a wide range of applications and materials

- Considerable technology advantages over current enclosed print media solutions

EdgeLoc® Snugging System

- MPM's EdgeLoc board clamping system takes board handling to the next level

- The EdgeLoc system uses software controlled pressure for the optimal board holding force, and automatically adjusts to match the programmed board thickness

- This unique solution firmly holds the board without the use of top clamps; delivering optimal stencil to board gasketing which is proven to yield higher paste release efficiency and reduced need for under stencil wiping

RapidClean

- A high speed stencil cleaning solution that improves stencil cleaning performance and reduces cycle time when using solvent

- RapidClean’s advanced plenum combines a vacuum and solvent stroke into a single wiper stroke

- Reduce 3 wipe strokes to 2 for a solvent, vacuum and dry cycle, which is the most effective cleaning sequence

- When using solvent, RapidClean reduces stencil cleaning cycle times by 5 – 6 seconds over the standard wiper

Paste Height Monitor

- Effective solution designed to prevent defects caused by inadequate paste on the stencil

- Utilizes advanced software and sensor technology for monitoring the paste bead for volume consistency

- When a low paste level is detected, paste can be added automatically using the dispenser or manually

- Easy to use, robust and highly accurate

Adjustable Stencil Adapter with Pneumatic Clamping

- A cost effective, easy to use solution for customers that need to handle different size stencils

- X - 20" (500mm) to 25.6" (650mm)

- Y - 20" (500mm) to 25.6" (650mm)

- Thickness: 0.39” (10mm) to 1.25” (32mm)

- Can accommodate tubular frame stencils, cast frames and space saver stencils

- Simply remove the adapter to use 29" x 29" stencils

- For smaller stencil sizes, the adapter can stay in the machine and you simply need to slide the stencil in and out when changing stencils

SPI Print Optimizer

- Produce consistent & accurate print results

- Reduce or eliminate operator “tweaking”

- Prevent defects instead of just identifying them

- Compensates for uncontrollable or difficult to control process variables